Taram is not just the name of a character in Walt Disney’s “The Black Cauldron”; it is also (with an extra ‘m’) the name of a French foundry that is back on its feet just 15 months after its installations were wiped out by a devastating fire.

On 24th February, the company officially inaugurated a new site at Mazères, in the Ariège department in Southwest France, replacing the facility at Labège, near Toulouse, that was 80% destroyed in the December 2015 blaze.

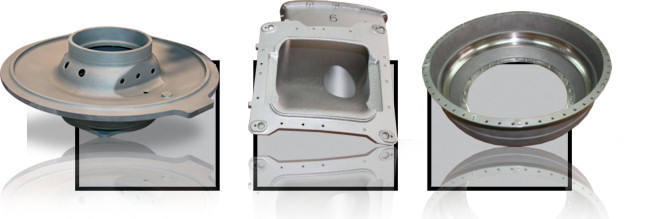

Taramm is a specialist in investment casting of titanium and high-melting-point alloys using the “cold crucible induction melting” process. Production is almost exclusively intended for the aerospace market.

The move to new facilities was already on the cards but the SME accelerated plans in the aftermath of the fire. Construction of a building at the new site was launched within days. Over the ensuing months, production continued at what remained of the old site and in the facilities of subcontractors. The first workshops were moved to the new site in July 2016, followed by the furnace; which came on line in the autumn. Most of the workforce also made the move to the new site.

A total of €10m was invested in the new buildings and equipment — autoclave, furnace, non-destructive testing (dye penetrant and digital radiography), electrical equipment and machining centres operated on subcontractors’ premises.

The Occitanie region contributed €900,000 in refundable loans from the European Regional Development Fund (ERDF) along with €350,000 for the new 3,000m2 building. A second work phase is due to get under way in April, at a cost of €4m, including a similar-sized building to accommodate machining, assembly and marking activities, and possibly a small dye penetrant testing line. This second phase is scheduled to be operational by this summer.

Site director Laurent Dardenne says production buildup since December has been satisfactory, though industrial performance is still short of targets. Deliveries are 1-2 months behind schedule (compared with 6 months in September) and only 10% of deliveries to Airbus are on time.

Aerospace customers are watching closely the output of this key SME with its specialized know-how. They appreciated its reactivity following what could have been a fatal blow to the company. Airbus procurement manager Raphaël Duflos was impressed by the speed and determination with which the management and workforce reacted to the fire. He says that Airbus has shown increased flexibility in response.

Taramm could well be included in the Airbus-centred cluster under the Performance Industrielles 2 supply chain performance programme initiated by France’s Gifas aerospace industries association, which could be launched in Occitanie in April 2018.

Today, Taramm regularly produces 130 parts references. It is a Tier 1 supplier for Airbus (Inconel tubing for A320neo and A350 engine pylons, and titanium secondary ribs) and supplies other parts for the entire Airbus product range via Latécoère and other subcontractors. For Safran, Taramm produces cast parts for Leap engines (10 parts for the Leap-1A, 24 for the Leap-1B and 8 for the Leap-1C). Not to mention Dassault, Latécoère, Sonaca and TAI.

To Dardenne’s regret, the company has so far been unable to penetrate the U.S. market.

The company, which logged sales of €11m in 2015 and €8.7m in 2016, has set a target of €14-16m for 2017, thanks to the creation of a “real marketing department” by the end of this year.