Safran Aero Boosters has completed the first full-size low-pressure compressor prototype intended for future ultra high-bypass engine configurations.

Safran Aero Boosters — a Belgian subsidiary of Safran specialising in modules, equipment and test cells for aerospace engines — has completed the first full-size high-speed booster (low-pressure compressor) prototype intended for new high-bypass engine configurations which aim to drastically reduce fuel consumption and noise.

These engines will require a compressor operating at significantly higher speeds — around 10,000 rpm, compared to 4,500 rpm for current engines such as Leap (for the A230neo, B737Max and C919).

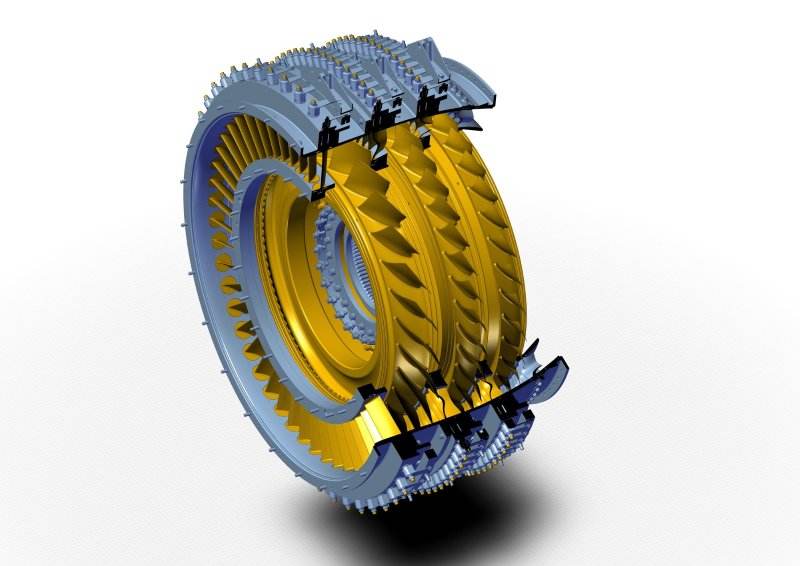

This next-generation booster incorporates blisks (integrally-bladed rotors) as well as stators with variable-pitch blades to optimise and regulate air flow. Made of more than 5,000 parts, this demonstrator has been developed as part of the European ENOVAL project.

Launched in 2013, the ENOVAL (ENgine mOdule VALidators) programme focuses on the low-pressure system of ultra-high bypass ratio propulsion systems (12 < BPR < 20) with ultra-high overall pressure ratio (50 < OPR < 70) of ducted geared and non-geared turbofan engines. This will result in a fan diameter increase of 20-35% vs. the year 2000 reference engine, which can still be accommodated within the limits of a conventional aircraft configuration.

These engines — expected to provide significant reductions in fuel burn (-3% to -5%) and engine noise (-1.3 ENPdB) — are seen as being among the best candidates for the next generation of short/medium range and long-range commercial aircraft entering into service from 2025 onwards.

Safran Aero Boosters is working with several long-standing partners including Safran Aircraft Engines, Russia's Central Institute of Aviation Motors (CIAM), GDtech and Cenaero, in addition to a host of local suppliers (Britte, Dardenne, V2i) and European suppliers (Lorentz in France, Praewest in Germany, and Seko in the Czech Republic).

The prototype is currently heading for Moscow to be tested on one of the few cells in the world capable of performing tests in simulated altitude conditions. For the Liège-based company, this marks a decisive stage in the preparation of its future products, which should be integrated into engines coming to market over the course of the next decade.