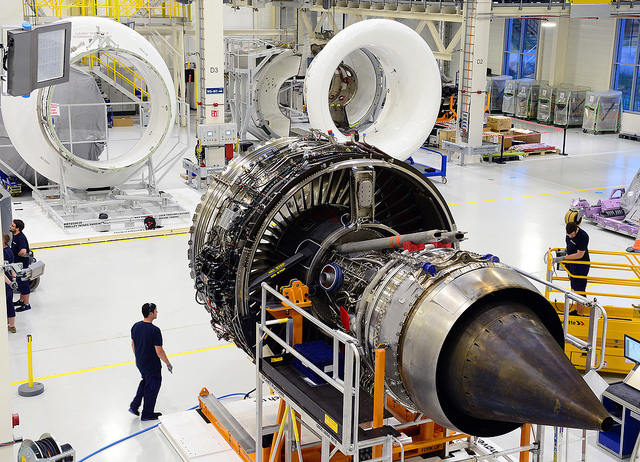

Rolls-Royce has officially opened a Trent XWB assembly line in Dahlewitz, Germany, which is due to deliver two engines per week by the end of the year.

Rolls-Royce officially opened a new assembly line for its Trent XWB engines in Dahlewitz, Germany, on 14th June, complementing its main production line in Derby, UK, and marking the first time that complete large civil engines have been assembled in Germany.

The new assembly line will help meet demand for Trent XWB engines for the A350 by delivering up to two engines per week by the end of the year. Combining this with the capacity to deliver up to five Trent XWB engines from its main production line in Derby means that Rolls-Royce will be able to deliver one Trent XWB engine per day at peak.

The Dahlewitz site, south of Berlin, was opened in 1993, and today employs around 2,500 employees. Aside from the assembly of Trent XWB engines, the BR700 engine family is also assembled on site, providing propulsion for large business aircraft, as well as the V2500 engine for the Airbus A320 family. Since opening, more than 7,000 engines have been shipped from the site.

The Dahlewitz site also plays a role in the development of the next generation of aircraft engines, hosting a test centre for the power gearbox system which will feature in Rolls-Royce’s UltraFan engine slated for delivery in the middle of the next decade.

The design of the assembly line benefited significantly from the application of virtual reality techniques developed by Rolls-Royce in conjunction with the BTU Cottbus-Senftenberg. The immersive technology, usually reserved for the design of new jet engines, allowed the teams to easily understand and improve the complex designs required, eliminating flaws early in the process and reducing planning time.