Lufthansa Technik and Airbus, working in Hamburg’s ZAL TechCenter, have developed a new coating technology that promises to cut fuel consumption.

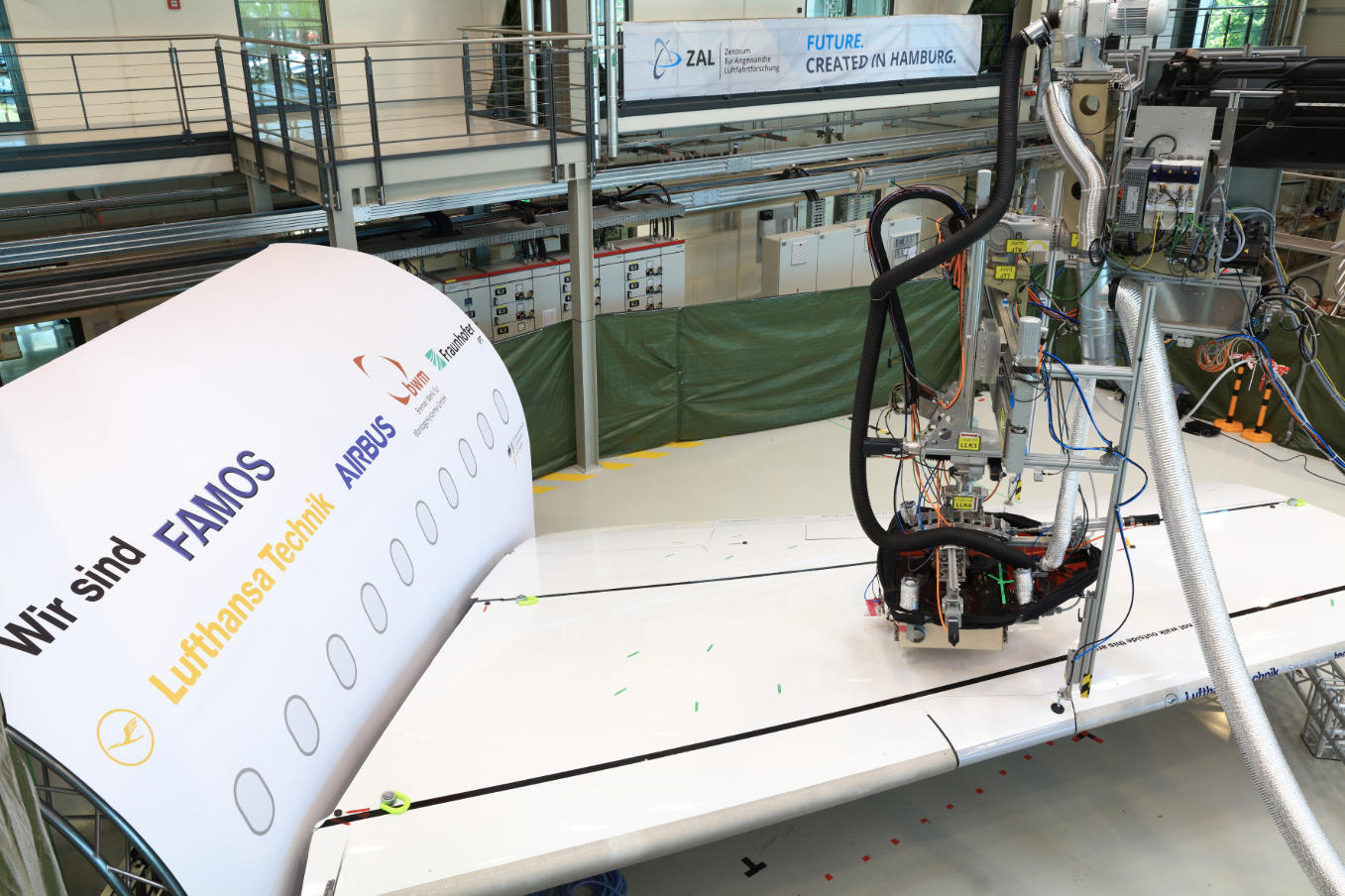

Airbus and Lufthansa Technik, have successfully completed a joint research assignment in the new 26,000m² ZAL TechCenter in Hamburg, which opened in March 2016. In the “FAMOS” project, the companies worked together to develop a system for using robotic arms to coat airliner wings with a “shark skin” texture. The surface, modelled on nature, reduces airflow resistance, thereby lowering fuel consumption.

The cooperation, which has Bremer Werk für Montagesysteme (bwm) as an additional partner, has also received funding from the Federal Ministry for Economic Affairs and Energy (BMWi).

The aviation industry has been investigating surfaces that reduce friction and drag for several years. The benefits of a so-called “riblet” structure, modelled on the skin texture of sharks, are obvious: the improved surface can reduce the fuel consumption of an airliner by around one percent. For Lufthansa’s fleet alone, this would generate savings of €55m worth of kerosene and more than 200,000 tonnes of CO2 every year.

Until now, the application of the “shark skin” structure to larger surfaces such as wings has proven difficult. Since 2014, the “FAMOS” project has been studying a solution that enables large areas such as wings to be painted and coated using a robotic arm; the automation means that the work is cost-efficient without sacrificing quality.

The project that developed the guidance system has been funded as part of the Federal Ministry for Economic Affairs and Energy’s fifth Aeronautical Research Programme (LuFo V) since 2014. Now that the project has come to a successful conclusion, including the construction of a functional demonstrator in the ZAL TechCenter, the next step will be to tackle the industrialization of the technology.