Lilium and its partner Customcells are accelerating the production of high silicon battery cells. The two industrialists are organizing themselves in order to be able to make the elements traceable in order to facilitate the certification of the aircraft and its propulsion system. The first flight of the compliant aircraft is scheduled for the second half of 2024 according to the manufacturer's schedule.

High Silicon Battery Cells for Lilium

Lilium and its battery cell production partner, Customcells, are ramping up production of high silicon battery cells with weekly deliveries from Customcells' production line in Tübingen, Germany. The production line aims to deliver thousands of cells per year and is on track to meet aviation standards for traceability and process control, using a combination of standard cell production processes and a pre-lithiation process for high silicon cells.

A pre-lithiation process

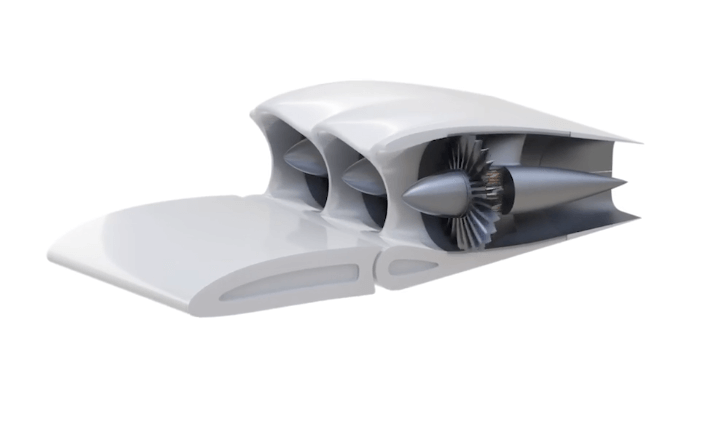

Lilium is partnering with Ionblox for its proprietary silicon anode cell technology that will enable higher energy and power density combined with extended life. Following the announcement of their partnership in 2021, Customcells and Lilium are now successfully operating a pre-lithiation process that both companies continue to industrialize for volume production. The pre-lithiation process, a key benefit to enable higher energy and power density, inserts additional lithium to compensate for lithium loss during the first cycle.

First flight of the compliant aircraft second half of 2024

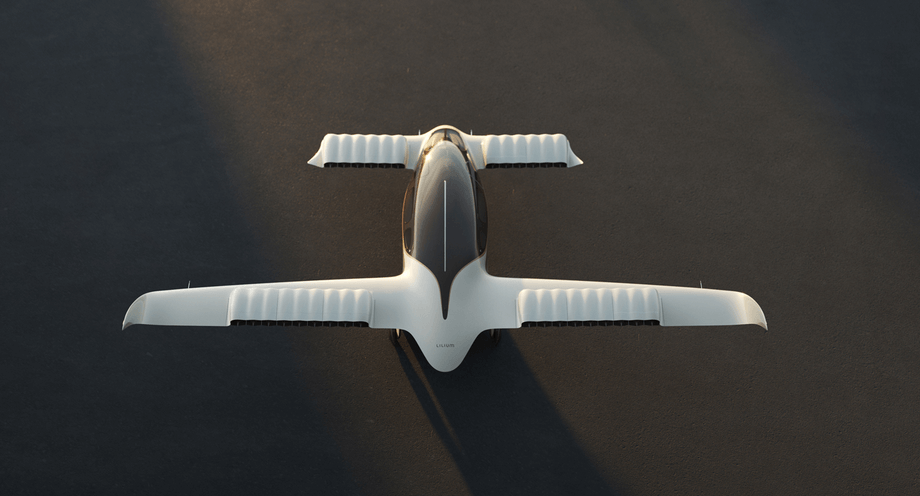

The traceability of Customcells' production will allow Lilium to meet aerospace standards eand meet production certification requirements by providing Lilium with process and airframe-level data. According to the manufacturer, Lilium remains on track to begin production of its type-compliant aircraft later this year and anticipates the first manned flight of the type-compliant aircraft in the second half of 2024. For Lilium, this agreement represents an important step toward final assembly of the compliant aircraft, which is scheduled to begin later this year. Lilium already has agreements in place for aerostructures, avionics, battery cells, power management systems, electric motors, propulsion system, aircraft interior and landing gear, among others. This announcement follows recent test results from an independent third-party laboratory that reported 88% energy retention - well above the 80% target - in the cells of Ionblox's prototype full-size battery developed for the Lilium Jet after 800 charge cycles at 100% depth of discharge (1C/1C cycles). These batteries will power the shrouded electric motors driving microblowers, with the assembly arranged on a moving trailing edge, allowing for level flight as well as the realization of the transition from vertical takeoff to level flight.

Découvrez cet article sur Air&Cosmos