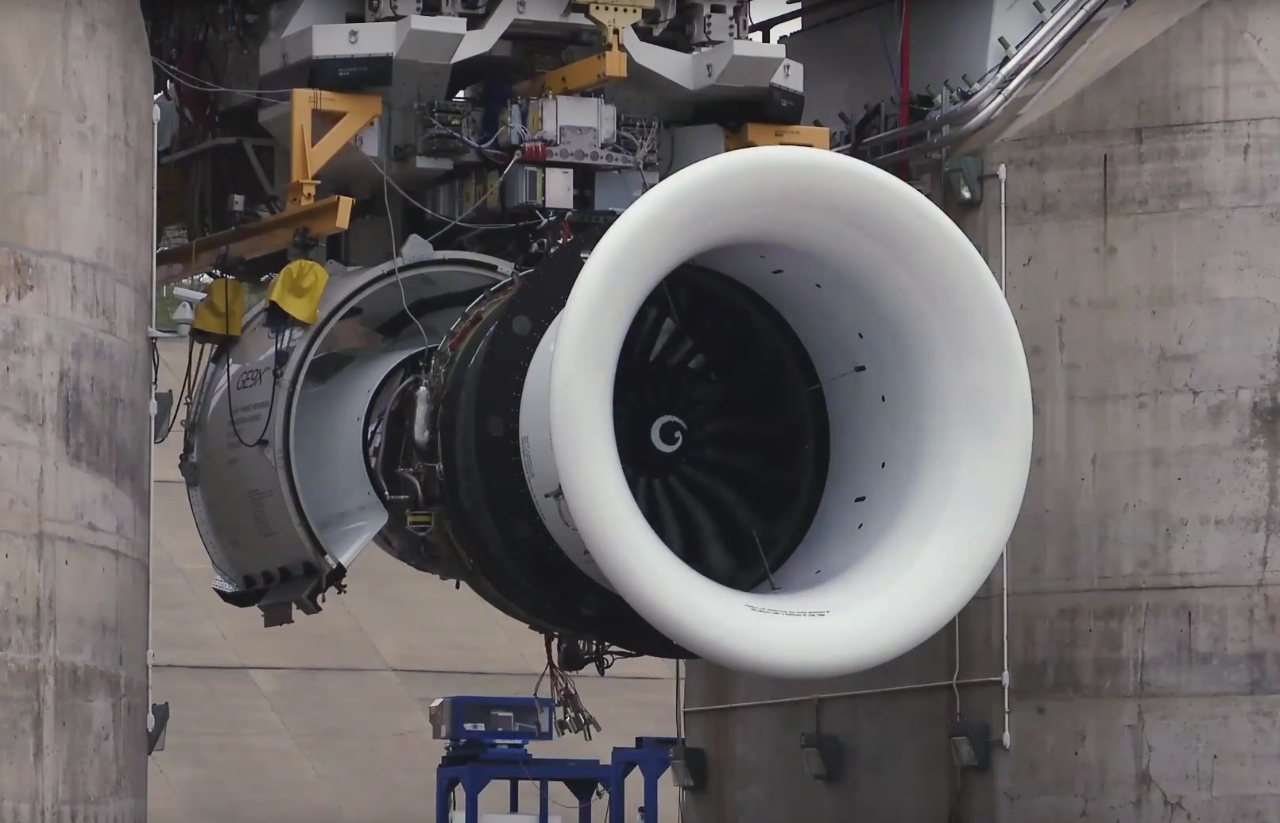

GE Aviation has started ground testing of the first full GE9X development engine at the company’s Peebles Testing Operation in Ohio. The GE9X will power Boeing’s 777X aircraft. Almost 700 engines have been ordered to date.

Maturation testing of the GE9X engine began about five years ago and has progressed from component-level through to the first full engine to test (FETT). FETT brings all the GE9X technologies together to demonstrate their operability as a complete propulsion system.

Compared to other engine programmes, the GE9X FETT happened earlier in the development process, six months after the engine design was finalized. The company says this timing assures all lessons learned from FETT will be captured in the certification engines. Next year will see the start of certification testing and flight testing on GE Aviation’s flying test bed. Engine certification is anticipated in 2018.

The GE9X will be in the 100,000lb thrust class and will have the largest front fan at 134 inches in diameter with a composite fan case and 16 carbon fibre composite fan blades. Other key features include; a 27:1 pressure-ratio, 11-stage high-pressure compressor; a TAPS III combustor for high efficiency and low emissions; and CMC material in the combustor and turbine.

IHI Corporation, Snecma and Techspace Aero (Safran), and MTU Aero Engines AG are participants in the GE9X engine programme.