General Electric has tested a 35%-additive manufactured demonstrator engine designed to validate additive parts in its clean-sheet-design Advanced Turboprop (ATP), which will power the Cessna Denali single-engine turboprop aircraft. The annoucement comes as the US giant pursues a major additive manufacturing push, including plans to acquire additive manufacturing specialists in Europe.

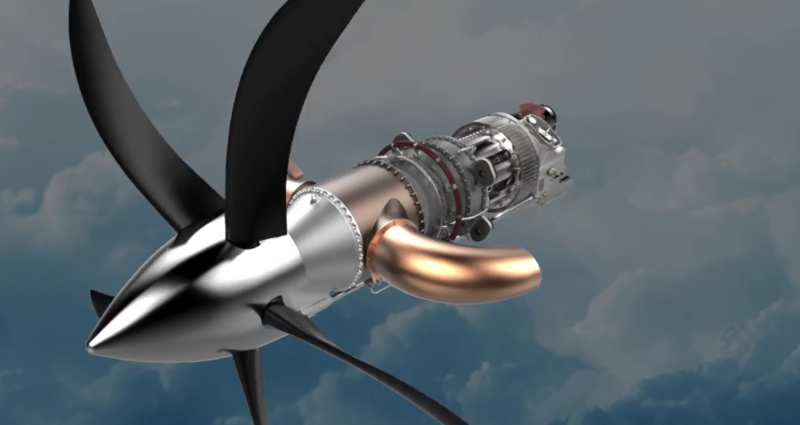

Additive components are expected to reduce the ATP’s weight by 5% while contributing a 1% improvement in specific fuel consumption (SFC). Aimed at business and general aviation applications, the ATP is targeting 20% lower fuel burn and 10% higher cruise power compared to competitor offerings in the same 1,000-1,600shp range.

An additive CT7-2E1 technology demonstrator engine, dubbed the a-CT7, was designed, built and tested in 18 months, reducing more than 900 conventional, “subtractive manufactured” parts to 16 “additive manufactured” parts. The ATP engine architecture is derived from the CT7, allowing for part commonality between the two additive test programmes.

According to GE, the ATP will utilize more additive parts than any production engine in aviation history; 855 subtractive manufactured parts will be reduced to 12 additive parts. Additive components constitute 35% of the ATP’s total part count. The 12 additive ATP parts include: sumps, bearing housings, frames, exhaust case, combustor liner, heat exchangers and stationary flowpath components. By comparison, the CFM LEAP engine includes one additive part category, the fuel nozzle tip.

The same team of eight engineers responsible for designing the CFM LEAP additive fuel nozzle tip led the design effort for the 16 additive parts tested in the a-CT7. GE is building more additive hardware for additional a-CT7 tests. The additive components for a-CT7 and ATP tests are built at GE Aviation’s Additive Development Center (ADC) in Cincinnati, Ohio. GE expects to run its first full ATP engine test by the end of 2017.

Key features of the new ATP engine include ruggedized, modular architecture; all-titanium 3D aerodynamic compressor; cooled turbine blades; and integrated electronic propulsion control.