UK Business Secretary Sajid Javid has announced that government and industry have committed to providing almost £365m (€427m) of funding for new aerospace technologies through the Aerospace Technology Institute (ATI). It is the largest batch of research & technology (R&T) projects to be granted funding since the ATI was created in 2013 to develop a technology strategy for UK aerospace. The funding announcement was made at the recent Farnborough Airshow.

The ATI-funded research projects will target different aspects of aircraft manufacturing and performance, with a view to driving up competitiveness, lowering costs, and helping to deliver environmentally-friendly aircraft with lower emissions and reduced noise.

The announcement builds on the £1.2bn of funding government has already jointly invested through the ATI, which has contributed to 149 new projects, involving 188 different companies and organisations, including over 100 small and medium sized businesses.

The 30 new projects involve 56 organisations from across the UK aerospace sector – including large Tier One companies, 23 supply chain companies, 12 universities, and a range of research organisations. They include:

- The £28m 4-year Large Landing Gear of the Future (LLGF) project, focused on landing gear design, analysis, performance and manufacture, and led by Safran Landing Systems.

- The £16.7m iCore project, led by Rolls-Royce with leading UK universities and suppliers, which aims to reduce overall engine fuel burn by developing aerothermal technology.

- A £3.5m project with the Aircraft Research Association (ARA) to develop specialist wind tunnel rigs and improve the performance of the Transonic Wind Tunnel.

- A £1m Flexible Robotic Machining in High Accuracy Applications project with the Advanced Manufacturing Research Centre (AMRC), to bring the benefits of high-accuracy robotic machining to the aerospace sector.

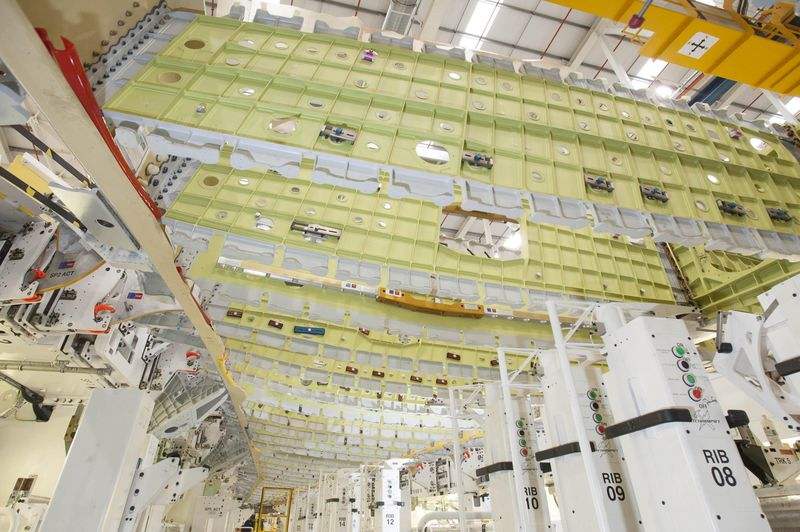

- The £17.7m Wing Design Methodology Validation (WINDY) project to develop an innovative way of designing and manufacturing aircraft wings, led by Airbus. UK engineering group Renishaw will be a key partner in this project, thanks to its expertise in metal additive manufacturing (3D printing) and precision measurement. WINDY will look at aerodynamic modelling of wings, the potential for use of complex 3D-printed components in wing structures and the possibility of innovative loads control on aircraft for better efficiency in flight.