On the occasion of the International Astronautical Congress, we interviewed Gérard Dejonghe, president of Erems, one of the main space equipment manufacturers in the Occitania region.

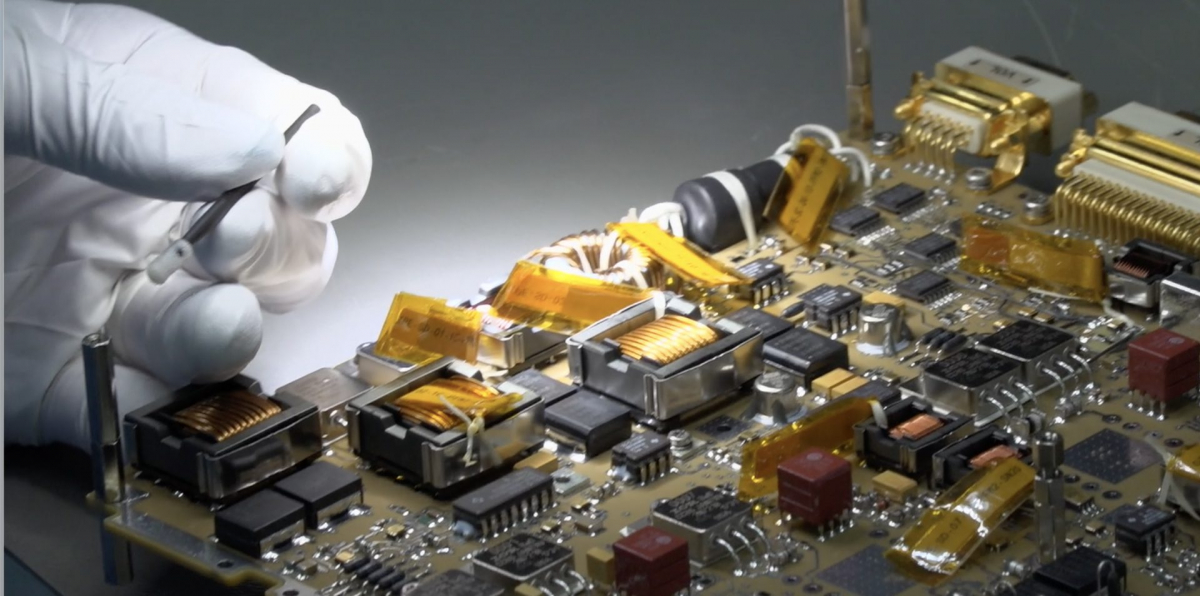

Created in 1979 in Flourens, in the eastern suburbs of Toulouse, the company Erems (Etudes et Réalisations Electroniques et Micro-Systèmes) works mainly for the space sector. On behalf of major contractors and space agencies, it has developed electronic equipment and associated software for several hundred missions of all types observation satellites (Spot 6 and 7, PeruSat 1, Pleiades Neo, MicroCarb, Copernicus...), telecommunications satellites (Eurostar 3000, Spacebus Neo, Eurostar Neo, Iridium Next...), scientific programs aboard manned spacecraft (on the U.S. Space Shuttle, the International Space Station and even the Chinese laboratory Tiangong 2) and interplanetary probes (Soho, Rosetta, InSight, Hayabusa 2, Solar Orbiter, BepiColombo...). The SME, which has experienced strong growth in recent years, posted a turnover of €17 million last March, mainly in space, with more than a third of this figure coming from New Space activities. The company now has just over 170 employees and is increasingly turning to exports, which is why it will be present this week at the 73rd International Astronautical Congress in Paris. To accompany this dynamic, major work on its premises will soon begin.

Erems is a flagship of the Occitanie region. Is the latter still on a roll ?

It is clear that, for more than forty years, our company has always positioned itself as a player in the Occitanie region, which, in terms of space, is a European champion, if we can call it that. We have the entire value chain here, from design to integration, with infrastructure manufacturing, and with manufacturers who know how to call on us. There is a geographical concentration of skills, with traditional companies, but also start-ups that are now setting up in the region, such as Exotrail or Loft Orbital. For our part, we are very much in favor of everything that is cooperation and international competition, and therefore export : it is one of our priorities.

That explains your presence at IAC ?

Yes. We participated last April in the Colorado Springs symposium and we could not miss the IAC meeting, which is held this year in Paris. So we have a 9 square meter booth on the Aerospace Valley island, along with a number of French space players, especially from Toulouse. It's really an ideal place to establish new international cooperations.

What are the next Erems equipments to be launched ?

We are on board the Franco-American altimetry satellite Swot, which is to be launched in December using a SpaceX Falcon 9. In cooperation with TAS Belgium, we built the RTU (Remote Terminal Unit), which is at the center of the management of all the subsystem interfaces. Swot will enable the monitoring of the entire water cycle, from lakes and rivers to seas and oceans. We have also just delivered the computers for the two telescopes, Eclairs and MXT (Microchannel X-ray Telescope), which will be supplied by Cnes for the Franco-Chinese Svom mission. This mission will be launched next June on a Long March rocket, and will make it possible to measure gamma-ray bursts in the Universe in great detail. Finally, I would like to mention our involvement in the RIU (Remote Interface Unit) of the Mars Sample Return mission of NASA and the European Space Agency. This equipment, which was entrusted to us by Airbus, collects all the interfaces of the various subsystems of the European orbiter ERO (Earth Return Orbiter), and activates the subsystems according to the orders given by the spacecraft's computer: it is, I would say, the computer's right arm. Typically, we are there on electronics of the highest quality class, given the stakes of the mission.

Earth observation remains an important sector for you ?

Clearly. We have invested heavily in this field since 2005, and supplied a lot of electronic equipment for the Airbus Defence and Space fleet, which was completed last year with the Pleiades Neo 3 and 4, while waiting for the new generation CO3D (Constellation Optical 3D, scheduled for 2024), on which we are currently working : we are preparing the equipment for the first four flight models of the constellation, namely the proximity electronics of the video sensors, the management of the thermal control of the optical instrument, and then a very advanced and high-performance digital image processing and mass memory equipment. And this is where Erems has a very strong added value compared to traditional players, but also to startups: our ability to control the entire design cycle of an equipment using new technologies, and especially to validate them. Because it's not enough to have the right idea to use this or that electronic component ; we also need to be sure that the component will hold up to all the constraints of the space environment.

You've also put a foot in New Space ?

Yes, this is an important point for us : we've made a big shift towards New Space, which complements and amplifies our activities. We had started with Angels, the first nanosatellite prototype of the French sector, launched in 2019, for which we had developed and miniaturized the electrical distribution module PCDU (Power Conditioning and Distribution Unit), using commercial components and qualifying these components to radiation. Since then, we have contracted on all of the power distribution equipment that is on board Hemeria's 25 nanosatellites for the Kineis Internet of Things constellation. Today, we are starting to hit, I would say, medium-sized constellations. This summer, we were selected for three calls for projects on new technologies for small nanosatellite constellations, to develop new architectures for mass storage, high-resolution video sensor proximity electronics and power distribution technologies.

So your R&D is an asset ?

Surely. At the last SmallSat conference in Logan, one of the issues raised was the problem of the coming increase in solar flares in the next few years, which is bound to pose a danger to the instruments on board the satellites if precautions are not taken, especially on New Space technologies. This is where Erems really has a card to play, because during our designs, we have in-house experts on everything from electrical analysis to reliability analysis to radiation protection. And we have the capacity, with the support of local partners, to carry out research and testing to find the right components that will withstand the radiation. In any case, it seems important to us that traditional space players and new entrants work together to provide innovative solutions to serve the ambitions of European space.

Can the return to the Moon be an opportunity for you ?

The Artemis program of course represents a certain stake for us. Since the beginning, we have always been involved in solar system exploration programs and manned flights : we have equipment on Mars, others that have gone to Mercury, some that orbit the Sun. So the Moon is interesting for us in several ways: the lunar station part, on which Thales Alenia Space is working, but also ESA's EL3 lander program, on which we will clearly position ourselves - subject, of course, to the decisions of the November ministerial conference. At the moment, we have discussions on several subjects for potential cooperations with Sodern, with TAS...

Meanwhile, you have very down-to-earth concerns...

Yes, we are going to start work on our premises in November. This involves refurbishing the current building and building a new wing, taking into account environmental issues, since we will have a large photovoltaic surface to supply us with electricity. This will allow us to better accommodate the 180 people who work on site today (including external support), but also to optimize flows, with the objective of greatly increasing our current production capacity, to continue to meet the needs of our customers, both old and new. This represents an investment of more than 5 M€, which will allow us to have a surface of a little more than 4 000 m2, with a size of clean rooms that will be doubled (about 500 m2).

Découvrez cet article sur Air&Cosmos