Avio Aero will produce the additive-manufactured components of the General Electric ATP (Advanced Turboprop) engine for the general aviation market.

Avio Aero, a GE Aviation business that designs, builds and maintains aviation engines, will produce, at its Brindisi plant, the additive-manufactured components of the General Electric ATP (Advanced Turboprop) engine, for the general aviation market.

The additive manufacturing machines will be installed at the Brindisi facility from 2018 and the first production activities will start between the end of 2018 and the beginning of 2019.

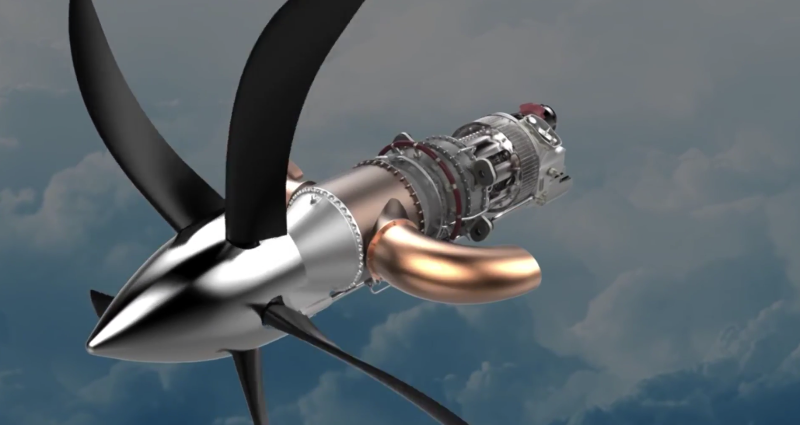

The ATP, an all-European project led by the Centre of Excellence for engine development established in Italy, is the first turboprop to include 3D-printed parts: 13 components, ranging from the combustion chamber to various structural elements, which have reduced the total number of parts in the engine by about 30%.

After Cameri (Novara), which specializes in additive manufacturing using the EBM (electron beam melting) technology, Brindisi is the second Avio Aero plant to adopt an additive process, although this time using DMLM (direct metal laser melting).

The Italian government is considering additive manufacturing as one of the most important enabling technologies to address the aims and objectives pursued under the National Industry 4.0 Plan launched at the end of 2017.

The Italian Ministry of Economic Development has undertaken actions to support Avio Aero's initiative in Brindisi as part of a broader investment project proposed by Avio Aero that is seen as a significant contribution to the digital transformation of the manufacturing industry in Italy.

General Electric’s new 1,300 SHP-rated ATP (Advanced Turboprop) is the first entry in GE’s new family of turboprop engines in the 1,000-1,600 SHP range. It has been selected by Textron Aviation for its all-new, single engine turboprop—the Cessna Denali.

The company announced in November 2016 that it had tested a 35%-additive manufactured demonstrator engine designed to validate additive parts in the ATP.